28 January

Breaking it down with Nelson composters, Greenwaste to Zero

At decent packaging, we strongly believe in focusing on the end of life for all our products, just as much as the fit for purpose design for our customers. Because, unfortunately, New Zealand is in a waste crisis. Despite everyone’s best efforts, most plastics are not recycled, landfills are full of food waste, and inconsistencies in waste management infrastructure nationwide are causing major confusion.

We see this waste crisis as a multi-faceted problem that requires a multi-faceted solution, compostable packaging is just one part of that solution, and if we all collaborate, we can succeed. Luckily, we’ve already got some local legends paving the way in commercial composting.

We caught up with Nelson commercial composters, Colleen and Jason from Green Waste to Zero who have been Breaking It Down for over 17 years. Read, share and support their journey, because increased knowledge and understanding of waste streams will empower people to drive change with their local communities and perhaps build local composting facilities of their own so that we can all get organic waste out of landfills.

Hey green-team, here's an easy question to begin, what motivated you to take over at Greenwaste to Zero?

We previously owned a retail store for 10 years. When we sold it we looked at other businesses to buy for a year before we found something that interested us. When we first viewed the composting facility we immediately knew it was what we both wanted to do. We loved the whole concept and feel of the business, it suited us perfectly.

Can you tell us what exactly it is that you do?

How it works is customers bring in their green waste, we mulch it and add it to our windrows, which are the large piles of compost. Every few months the windrows are rolled forward which allows us to control the moisture and temperature levels. The very last windrow is screened, then fine compost is stored in a big shed to keep it dry and stops any birds or the wind spreading seeds.

The 'tailings' from when it is screened (tailings are the larger pieces that pass through the screening plant as they are still too big) are added right back to the first windrow to go through the process again, so nothing is wasted. The whole process takes about two years.

What would you say the hardest or most challenging part of running Greenwaste to Zero is?

The weather certainly controls us a lot. Wet and cold weather means people don't get out in their gardens as much, hot and dry weather can mean droughts, so not much growth. Luckily since we took over the business a year ago, the weather has been very kind to us. The only other concern is our machinery. We have large equipment that cost a lot to run, and breakdowns can be quite stressful.

On the flip side, what's the most rewarding part of owning Greenwaste to Zero?

That's easy, it's the positive feedback we get from our customers regarding the quality of our compost. It is also awesome to hear from our local council that they fully support what we do. We’ve had many comments about how much we have improved the business from the previous owner.

Amazing! What does an average week look like for you?

On a Monday morning, all the weekend's green waste gets taken away from the pad where customers drop it off. It all goes down the back of the property where it is mulched. It can take up to three to five days to get through it all in the peak of the growing season.

We have a delivery driver who spends most of his time delivering the compost to customers and he gets very very busy in spring and autumn, so we don't see much of him then. We also have to screen the compost to make sure we have plenty to sell so during the busy seasons we can spend days and weeks screening.

During the day we have a constant stream of customers and garden contractors coming and going either dropping off their green waste or picking up compost, topsoil, mulch, stone etc.

There is generally a day spent on maintenance as this needs to be kept up. We take flax, but as our mulcher can't take it as it is too fibrous we have to cut it up manually into short lengths, which can take some time, especially when we get a lot in as it’s quite hard work.

It is a lovely job on a nice day though. Before the next weekend, we clear out all the green waste again and make sure we have plenty of bagged compost ready to go. And of course, all the administration is done in the background, to keep the finances running smoothly!

So it’s non-stop. Apart from individual customers dropping off their green waste you also work with some cafes and businesses to compost packaging from, how does this process work?

We just started doing this midway through last year, but since then there has been a lot of interest. We have about a dozen small cafes and food carts that bring us their compostable packaging, these are mainly coffee cups. However we also take the compostable chip packets from Proper Crisps who are Nelson-based, a local petrol station brings us their coffee cups and the public pool cafe and a college canteen are currently setting themselves up too.

We also take all compostable packaging from major events, like Bay Dreams, the Buller Gorge Marathon and fairs. We have more and more businesses joining especially since the local councils have introduced a 'no waste' policy, so all events now have to have compostable or reusable packaging. This means a wash station, to clean and reuse serve ware and all the compostable packaging coming to us.

It’s awesome to hear more and more businesses joining the garden-path to zero waste as there seems to be an opinion composting packaging is only possible with high tech machinery and equipment. What does your set up look like and are there any barriers for other individuals or community organisations to follow in your footsteps?

It’s awesome to hear more and more businesses joining the garden-path to zero waste as there seems to be an opinion composting packaging is only possible with high tech machinery and equipment. What does your set up look like and are there any barriers for other individuals or community organisations to follow in your footsteps?

To set this type of business up would be expensive as there is big machinery involved. We certainly don't have the fancy equipment that is available, specialised for this very purpose, but large, expensive to run and maintenance on machinery is required.

The green waste needs to be mulched before adding to the windrows, the compost piles need to get to high heat to be effective and if this can't be done then the compost simply won't work. The windrows need irrigation if they are too dry and they need cooling when they get too hot. Sometimes this has to be done immediately to prevent fires. All these steps take equipment that can use a lot of diesel, need plenty of maintenance and repairs as the green waste and compost can be quite harsh.

Space is also another hurdle. You need plenty of room to store the green waste before mulching, space to roll the rows, and you need to be able to sell the compost at the other end of the process to prevent congestion. Resource consents will be required from the local council, one of which will mean you need a leachate pond. This needs to be a sizeable catchment pond for any runoff or leachate from the windrows. We have 2 hectares here just for the composting side of things and the office, shop and landscaping yard is extra land on top of that.

As decent packaging is made from plants, it needs all these same requirements as green waste to break down properly. So, the whole process is relatively simple but reasonably costly, time-consuming and requires plenty of room, not to mention approval from your council.

Have you seen a shift in public interest about composting since you started?

It has been huge! There won't be a week that goes by where we are approached by an organisation, newspaper, community group, cafe, school, event facility looking to compost their packaging. It is really encouraging that we are getting the support. We aren’t really making any money from the compostable packaging, but it makes us feel good!

If you could give a few tips to people trying their hand at composting food scraps and packaging at home, what would it be?

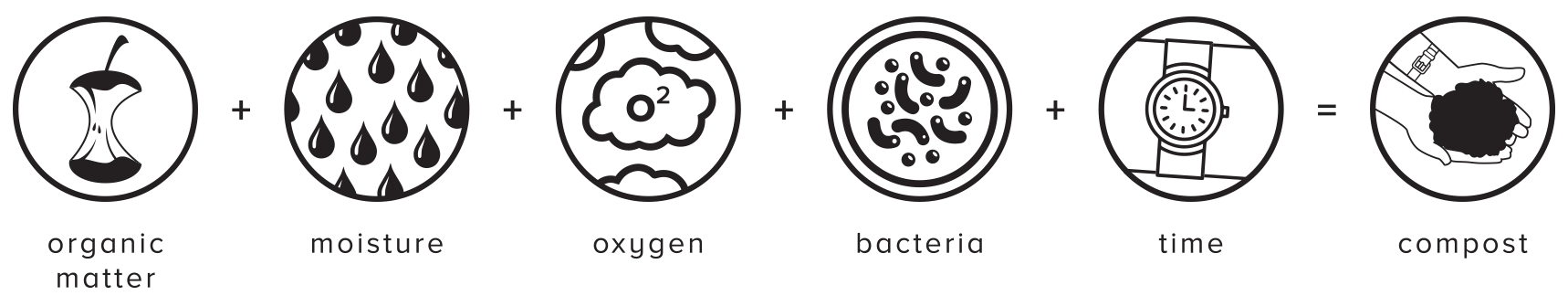

Home composting can be difficult to get it right. You need to make sure it isn't too wet, too dry, and not just lawn clippings. There needs to be a good mix of green to brown material, the brown being sticks, twigs, dead leaves etc. Bearing in mind if the sticks are too big they won't be able to break down as quickly unless you can mulch it first. Cardboard, paper and compostable packaging also add to the brown. Avoid food scraps, particularly cooked meat as this will attract rats and vermin. Home composting tends to not get as hot, so keep it well aerated so oxygen can penetrate to the centre to encourage the microbe growth.

What do you think the future looks like for Greenwaste to Zero and for composting/waste in general?

We feel we have come a long way in our understanding of the whole circular economy since taking over this business, and have thoroughly enjoyed the process. We do believe composting is an important process in reducing greenhouse gases and landfill which is damaging our environment. Communities and councils are all aware of this and are actively doing what they can to encourage sites such as ours. There are other systems available now that compost food scraps safely, with no harmful emissions that we would love to invest in. Food scraps and wastage is certainly another big area that can be and should be, addressed. We hope to get on board at some stage with this.

Do you have any parting words of wisdom or advice for eco-conscious kiwis?

It's the only way forward. It's the future, so we need to start preparing for more compostable products. I am sure there will be a point where no more packaging will be allowed unless it is compostable. We are already seeing some events only being permitted with zero landfill waste and this will no doubt extend to all events in the not-to-distant future. We have to protect our planet, and we are proud to be able to support this.

At decent, our packaging is certified compostable, meaning it has been tested and is guaranteed to fully break down back into organic matter. Our bagasse range is certified home compostable to the TUV Okay Compost home compostability standard, while the rest of our range is certified to international standards EN13432 or D6400/D6868 which means it is certified to compost fully within 12 weeks at a commercial compost plant. The key reason some of our range needs to be commercially composted is because of PLA, the corn-derived bioplastic that some of our products are made from or lined with requires 60-degree heat to start breaking down.

This means your decent packaging noodle container bagasse bowl with the mung beans you’ve eaten around can all go to the same place. No separating, no cleaning and no rinsing, just all in one compost bin.

We’re lucky in Aotearoa that there is already a number of organics collection services already set up, you can find them all listed here.

However, while there isn’t commercial waste infrastructure nationwide, we’ve established a compost return scheme - Closing the Loop, by decent packaging.

Purchase a 'Closing the Loop' pack and you'll receive two Trash bag liners, an easy to follow info sheet as well as a return courier sticker. Once you've received your pack, just follow the info guide and you'll be saving any compostable packaging from going to landfill. Learn more about closing the loop it here.